After half a lifetime working in pathology, I was asked to join In 1980 I was invited to join the Ernst Leitz Microscope division in Sydney. My only sales experience had been selling newspapers and magazines at our wharf to commuters when I was at school. I was pretty good at quick calculations in pounds, shillings and pence to give change. But selling microscopes?

I did know a bit more about microscopes after using them for 20 years in labs in Sydney, Johns Hopkins Medical School, in research and in London. So at least I had the basis for my new career. It also brought some travel bonuses.

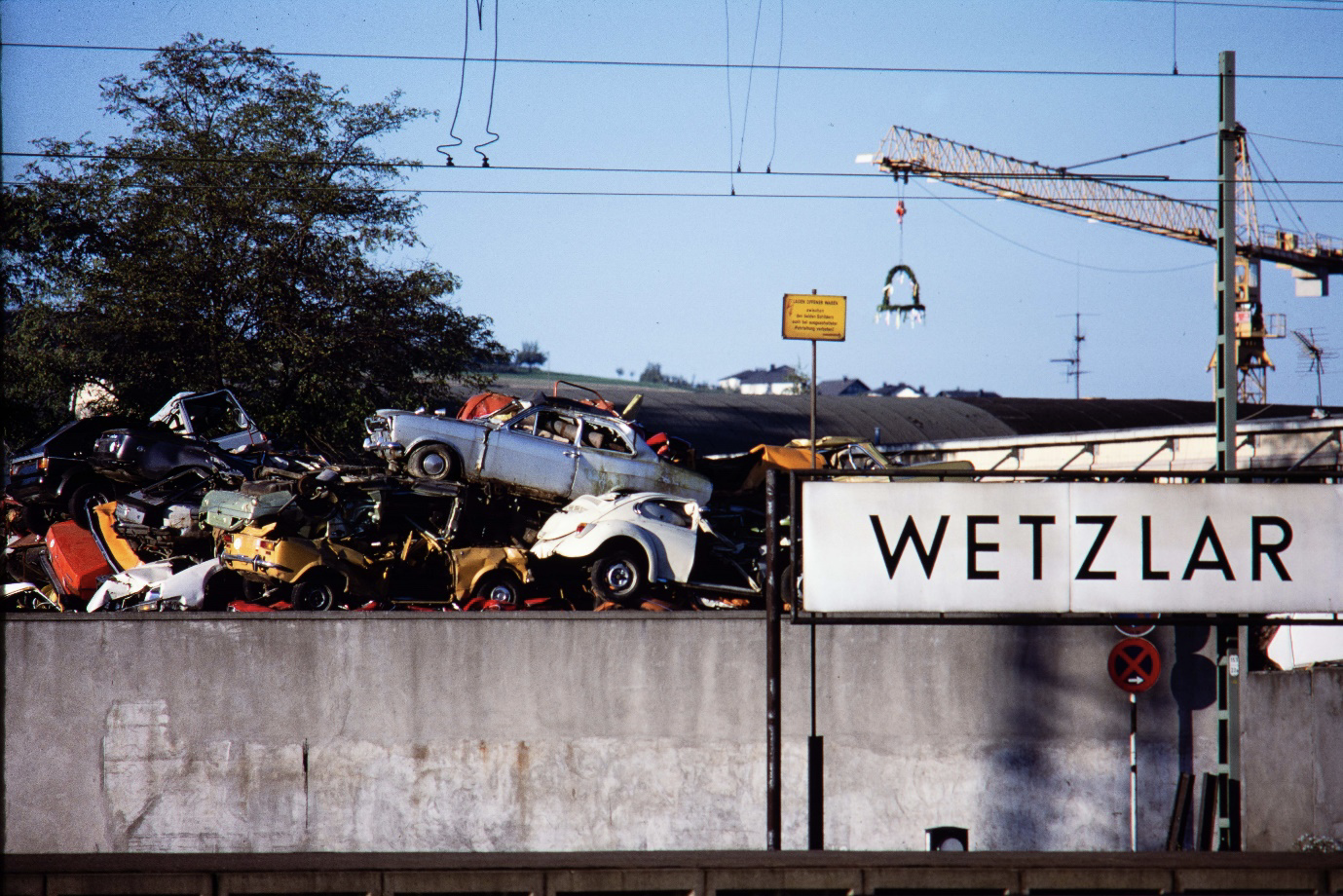

In 1985 I was sent to Wetzlar for advanced training, with a small group of Leitz salespeople from all over the world. We came from Canada, Pakistan, India, El Salvador and Australia. We started with an examination to see where we were weak in our knowledge. The course was really valuable in improving our theoretical grasp of microscopic techniques.

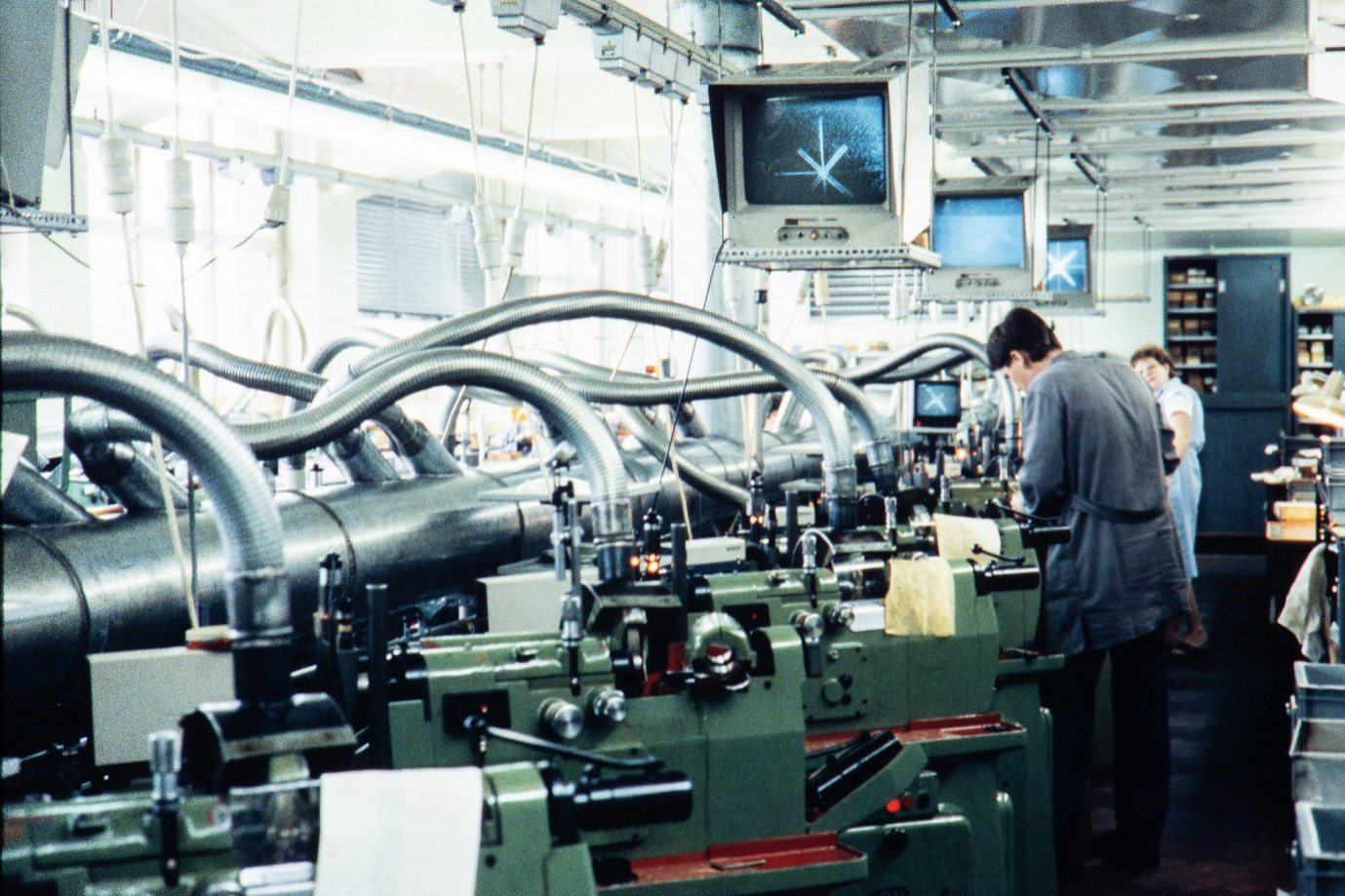

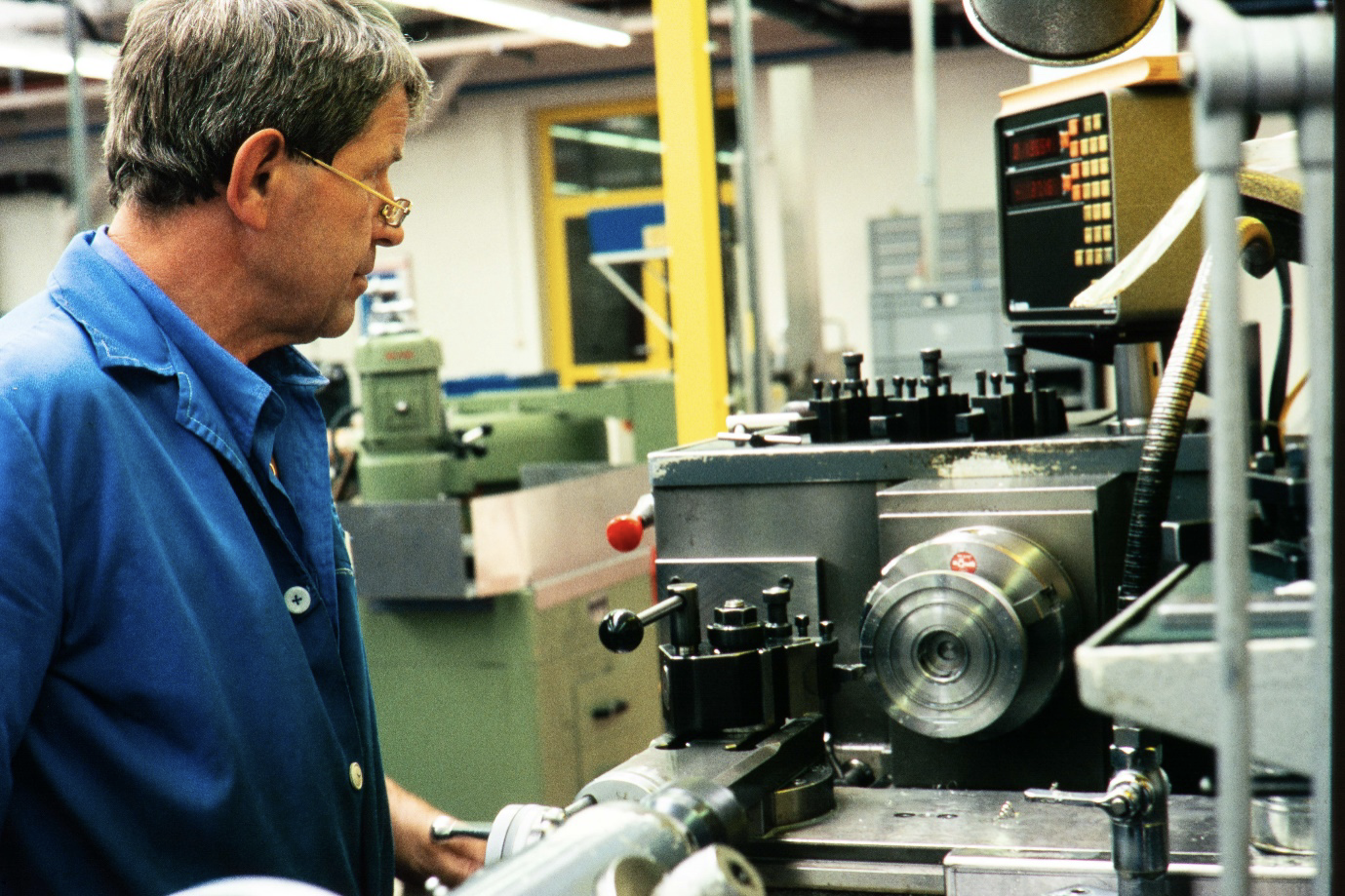

As we were considered staff, we were taken all over the original factory in the old town of Wetzlar. Cameras and microscopes were all made in the same area. We walked among the machines and spoke to the operators and, of course, took photographs. I had a Leica M4P and a Metrastar meter. My lenses were Summicron 50 and 35 mm. I used Kodachrome 25, a very unforgiving film with fluorescent lighting. Colours have been corrected here in Lightroom after digitally copying the Kodachromes.

The glass bank

The glass bank was just a room with very strong shelves. We were given blocks to hold, different types of glass, to feel the weight. The surprise was the block of high-refractive-index, low-dispersion glass. This allows lens elements to be thinner and lighter than would be possible with crown or flint glass. This glass is cooled from the melt slowly over a period of up to a year in platinum crucibles. This avoids strain patterns developing in the material, a problem for polarisation.

The glass was used originally for microscope objectives which are very small compared to camera lenses. This possibly explains the cost of some glasses. The blocks were cut into slices before grinding to shape. Optical and physical centres were measured using a target and TV screen, then the lens was ground to have these precisely aligned. All so different to the methods used today where blanks are moulded to an approximation of the size and shape required then ground individually on separate machines.

Microscopes

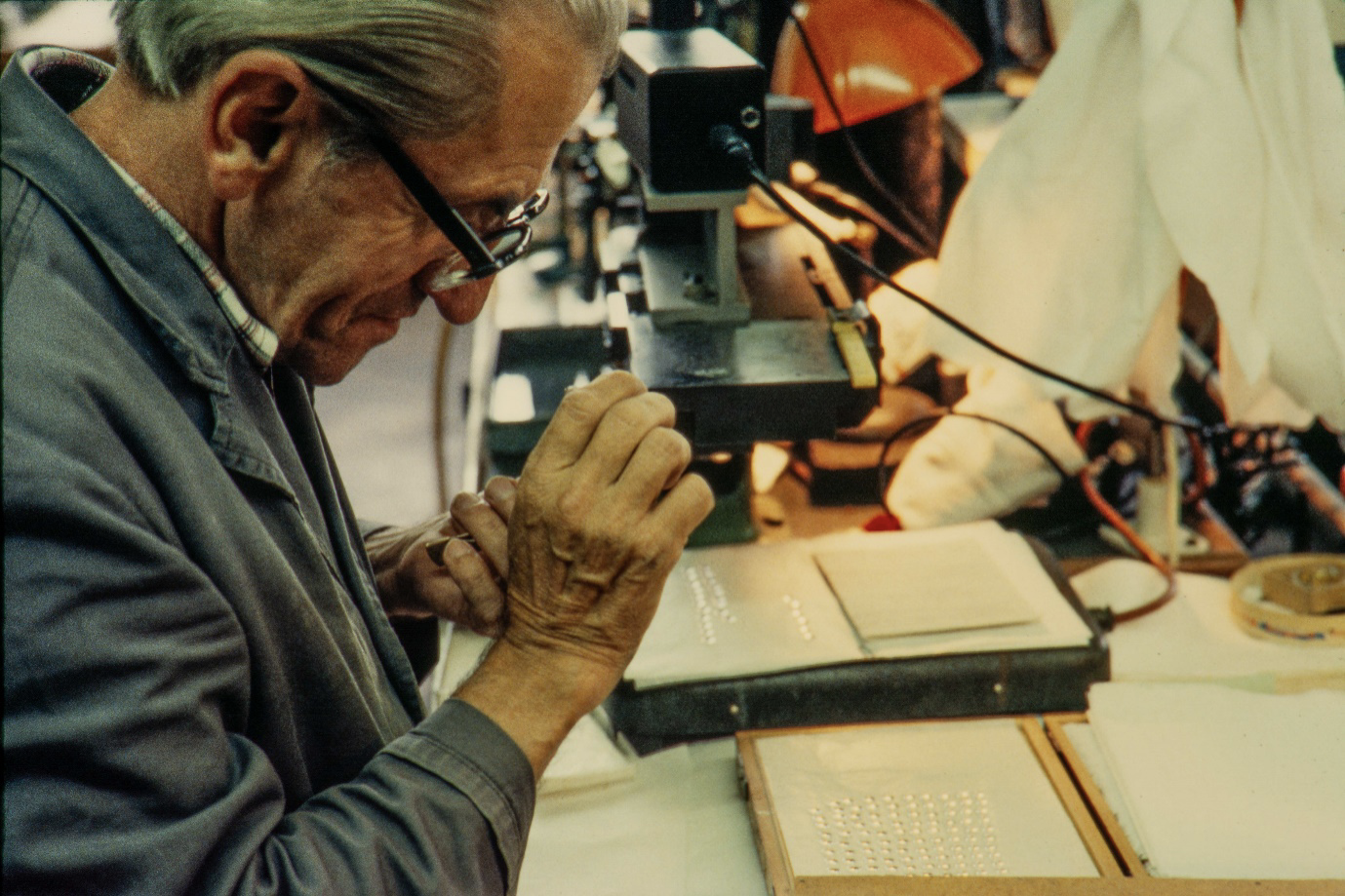

Everything was open and looked primitive, but continuous testing was still carried out and there were boxes of rejects near all the machines. Some glass could be re-used but prisms and lenses were there to be collected by hoarders like me.

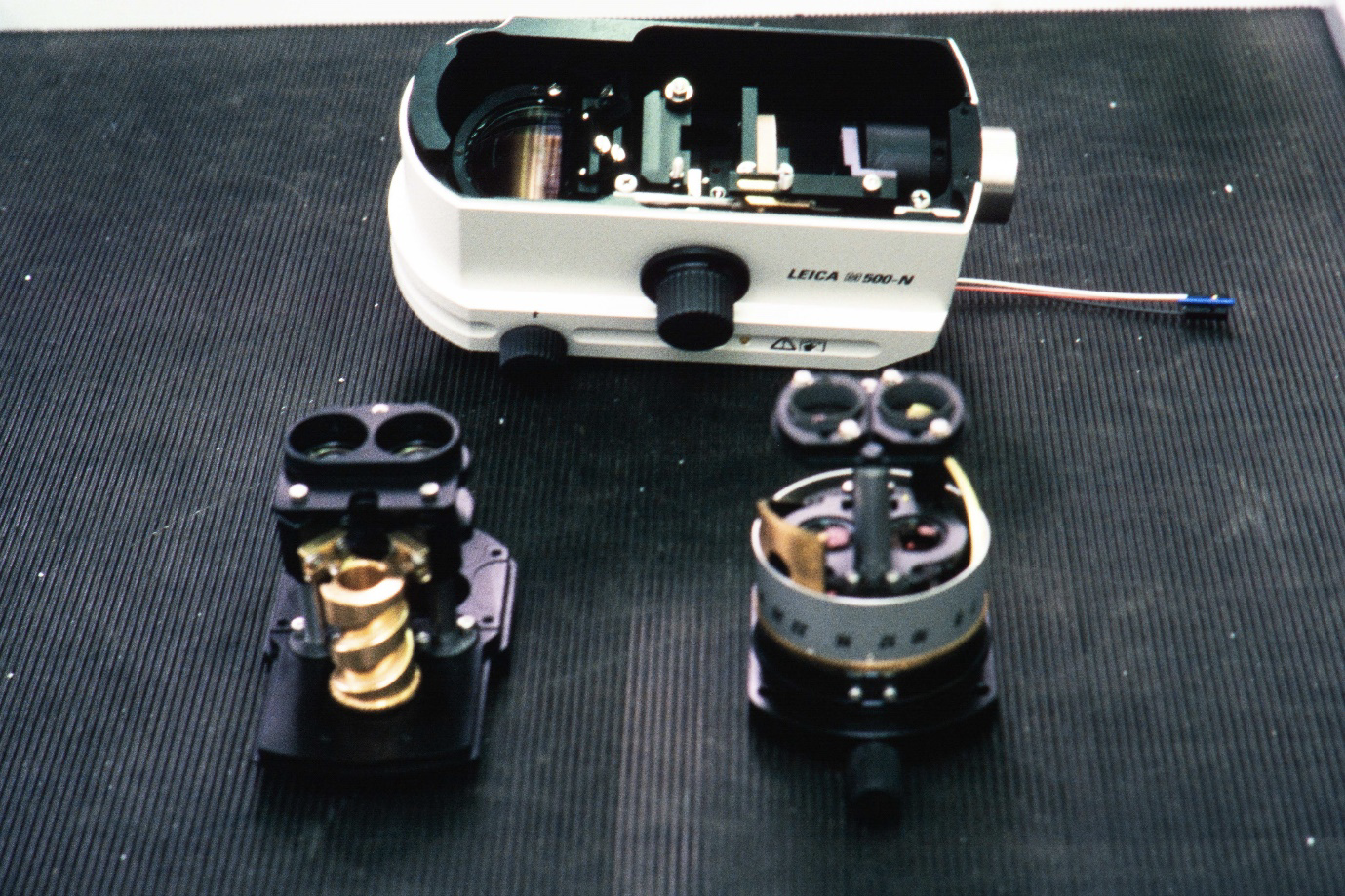

Leica in Wetzlar and Heerbrugg make cameras for microscopes. These cameras have leaf shutters and viewing and focusing through a telescope or through the binocular head. The metering is via a separate box with button controls and enables spot or wide-field metering with an override for dark field. They are very sensitive and can read fluorescent images.

Leica was a very early adopter of digital imaging and made digital cameras for microscopes before these were available for the consumer market. One camera in the product line could be used continuously until the hard drive was filled. Heat is a problem so a Peltier cooling system was incorporated into the camera. It was very sophisticated.

On many subsequent visits to Wetzlar, Solms and Heerbrugg I have seen great changes in technology and machines used at Leica. The overriding principle has always been quality control. This is seen at every stage of manufacture and some of the testing equipment is very sophisticated. Tolerances are much tighter than those used by other manufacturers in lens element curves, spacing and metal measurements. The amount of manual labour and skills of staff is very evident in the old photos and on a visit to Leitz Park now.

Make a donation to help with our running costs

Did you know that Macfilos is run by five photography enthusiasts based in the UK, USA and Europe? We cover all the substantial costs of running the site, and we do not carry advertising because it spoils readers’ enjoyment. Any amount, however small, will be appreciated, and we will write to acknowledge your generosity.

Thank you.

Thanks Philip, an interesting weekend read and time capsule images.

A significant mid life change for you. Anything more about why you made the change from pathology (technical, I’d guess) to sales? And how it was that the Microscope Division found you?

You convey a whole world of its own, both historically and actually. Completely unknown to me before. Thanks for enriching my multiverse!

Phillip, thanks for sharing memories and photographs from the “old Leitz days”. It brought back pleasant memories, when I, like you went to Wetzlar for microscope sales training. This was in December 1969. Apart from the manufacturing facilities in the old building, I remember being fascinated by the “Pater Noster” continuous, open no door “walk in-walk out” lift system between floors. No button pressing and waiting for a lift to arrive.

Alan

Ah, the Pater Noster lift. I have a business involvement with a physiotherapy clinic with offices in Athens and Berlin. Our Berlin building, on Wittenberg Platz opposite KaDeWe, is probably mid-eighties but has a working Pater Noster. It is banned for patient use for obvious reasons. You need to be rather fleet of foot to jump on. There’s a good reason it’s called the Our Father! They were definitely popular in Germany especially.

As a student (LONG ago…) I visited a Swedisk company that had such lifts in their office building. Out of curiosity, I remained in place when going down past the lowest floor (trusting blindly that the safety regulations wouldn´t let anything really gory happen to anybody doing just that). Pitch dark, but I did feel a distinct sideways transition (at least I didn´t emerge upside down), so I suppose the compartments all hung from some main belt in such a way that they form a gap-less progression.

But, I´ll never forget the expression of the guy that tried to enter my compartment knowing he was at the bottom floor, and found it already occupied….

Never tried that, Per, but I don’t think I will give it a go. It never occurred to me to wonder what happens at the bottom…

As an undergraduate at the Department of Chemistry, Imperial College in London in the 1970s, I first encountered a paternoster which allowed efficient movement between the many floors in the Chemistry building. With just a little courage, one could hop on to the the door-less compartment, travel up or down to the destination floor and then hop off. So much time was saved compared to summoning an elevator and then waiting for it to arrive. One day I took a big gulp and remained in the paternoster compartment as it rounded the uppermost phase of its travel, passing through a pitch black region where the sound of the motor dominated the soundscape. I survived, and found myself heading downwards towards the lower floors, safe and sound. I understand that the paternoster has since been replaced with a conventional elevator. Too bad!

I just look up how these things work. I can’t imagine how a body moves sideways to the compartment going in the opposite direction. It is probably a simple solution when you see the diagram.

December 1969 is interesting. I have a document, written by an F Neumann, from about 1969 which is called ‘A Visit to the Leitz Factory’ and which shows among other things students taking part in a course of microscopy at the Leitz Works. I am going to copy it for Philip and Mike and also send it to a contact at the Archives in Wetzlar, if they don’t already have a copy. Perhaps Alan you might be in that photograph? I’m happy to share the document with anyone who is interested.

William

Thanks William and I would love to view a shared document. Even if I don’t feature in a photo, it would certainly bring back memories of my time in Wetzlar.

Hi Jorg-Peter

It was certainly a different era

I collected rejected pieces from the boxes which I used in microscopy courses at Sydney Technical college. Where I taught for 20 years. Working for Leica at the same time. A young family has to be fed.

Leica, Linhof and Bolex were our other product lines

A good time to try them all. I still use 4x’5 and have my own darkroomCheers

Philip

Philip, It is great to see your article here. When I met you in Wetzlar in 2018, I had no idea that you had been there before in an ‘official capacity’. When I went down by the old factory last September, I did not have much time as I had an appointment back at the Archives in Leitz Park. I may try to visit this historic building the next time I am in Wetzlar. I would also like to share this fascinating look at the history of Leitz with some of the people working there at present. Leitz/Leica is a company that really values its history and, as Jorg-Peter says, this describes Leica’s philosophy to this day. Long may that last.

William

Dear Philip, thank you so much for sharing this insight. Seems, at the same time, to come from a remote past, and to describe Leica’s philosophy to this day. I was impressed to read that the link between microsope optics and camera lenses was so close in these days. And I liked to photos. On an M4 with Kodachome 25 (not the easiest way to go even back then), they are so much better than many images taken with today’s equipment. I particulary liked the image of the elderly man inspecting a small part of a microscope and the station scene with the scrap yard… Excellent article and photos – thanks again! JP